Stractive technology, a barrier against vibrations

Founded in 1949 by Giuseppe Genovesi, Dalmar opened for business in Milan in the segment of industrial tubes, operating in parallel on five lines of business, to become an entrepreneurial entity able to design and supply industrial solutions tailored to companies all over the world.

The Milanese company has a strategically important partnership with Hutchinson Paulstra, a company specializing in vibration isolation systems, acoustic insulation, and dynamic sealing devices.

Thanks to this collaboration, the Lombardy company can offer a wide range of steel or rubber anti-vibration supports. A particularly interesting one is the active anti-vibration system called “Stractive”, which acts in an active and dynamic way.

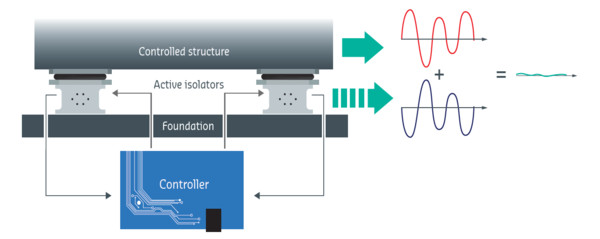

Unlike traditional anti-vibration mounts, which always work passively on the vibrations generated by the machine and do not always reach the desired level of insulation, Stractive eliminates vibrations through a dynamic force of equal amplitude

and in phase opposition.

To achieve this, the Dalmar device uses electrodynamic actuators that improve insulation even at low frequencies, often the most difficult to isolate, with a range of action between 10 and 1,000 Hz.

From silencers to electric motors, from internal combustion engines to carpentry, fans, machine tools, and textile machines, Stractive can be used in many mechanical sectors. Naturally it is also used in agriculture, where it is prized for its many strengths. “With our anti-vibration technology - the manufacturer explains with a technical note - it is possible not only to reduce the weight of the machine, because no additional weights are needed, or to facilitate its assembly, containing or eliminating the inertia masses, but it is also possible to reduce the stresses on the frame and the stresses on the joints and on the welds of the machine. And, of course, contain the noise level”. It’s worth mentioning the vibration isolation - from 12 to 36 dB of further decrease compared to the passive suspension of steel/rubber only - and the elimination of the most annoying harmonic frequencies, greatly benefiting the whole working environment. Stractive can be used on board of already assembled and operative machines (the modifications are minimal), with a reduction of spaces and weights. Compared to a passive solution of equal stiffness, this ensures an improvement of the dynamic insulation.