Depth Control by Rima: "hi-tech" processing

Depth Control is a new system for regulating harrowing depth creased by the Rima manufacturer. The system enables the operator to control the depths of the tines and regulate the height of work

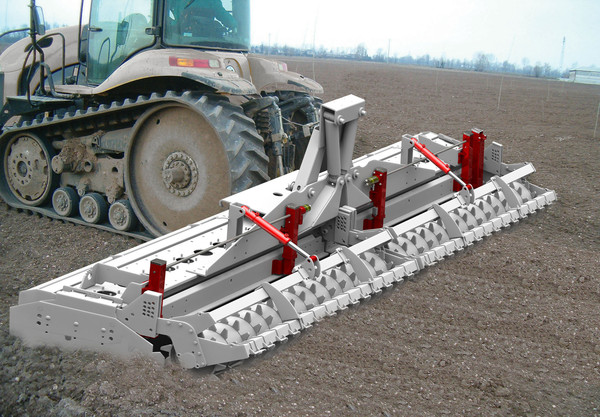

Its name is “Depth Control”, a depth control system for harrows developed by Rima, the firm from Brescia (the headquarters are in Montichiari), which allows to automatically monitor the length of the machine’s teeth and, if necessary, to change the working height by acting on the rear support roller. The smart device by the Brescia brand was designed not only to adjust the length of the teeth in a precise and detailed manner, but once that data is gathered, it also interfaces with the hydraulic system (through an electronic control unit managed on a display in the driving seat) and adjusts the position of the rear roller and the levelling bars. With the “Depth Control” system, the harrow can work at a constant depth (customized by the operator based on the different type of crop), optimizing on the one hand the yield of crops, and on the other hand the fuel consumption and operating cycles of the machine. This results in a significant savings on costs related to the management, maintenance, and wear of the application. “The rotary harrow is a machine used for the preparation of the seedbed after plowing, and is also appreciated for its high hourly productivity, which, however, is obtained if it is operated at a constant depth. Surveys and tests conducted on some equipment with the “Depth Control” system - explains with a note from the company based in Montichiari - have shown that intensive use of large harrows can provide a total saving of 25% compared to unprotected applications with this device.“