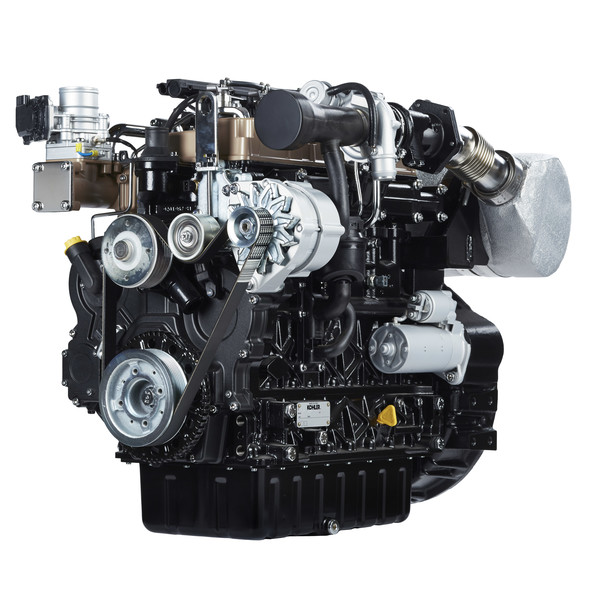

Kohler Flex, the integrated system of KDI engines

At Eima International, Kohler presents a further development of the KDIdiesel engine platform, with the addition of new models all conform to the Stage V. Already characterized by “green” combustion, KDI engines present the Kohler FlexTM technology, a range of emission filtration solutions that the German company has designed to allow each engine configuration of the KDI platform to meet the emission standards and regulations in all countries of the world. The strength of the FlexTM system is the clean combustion of the KDI engines, which, thanks to Stage V, allows the adoption of a compact and cutting-edge DPF. The DPF thus integrates with the high-pressure common rail injection (2000 bar) with four valves per cylinder, with the turbo-compressor and cooled-EGR. «Each FlexTM combination - explains the manufacturer with a note - has been studied from the point of view of the all-in-one philosophy, with the aim of minimizing modifications to the installation of the engine on existing compartments». The Stage V version is a functional solution for both manufacturers and end users. In fact, the regeneration strategy has been studied to optimize the operation of the machine, even at low loads and temperatures, thus preventing the stops caused by forced regeneration. Therefore, with the after-treatment system, it is also possible to increase productivity (greater load response and better specific performance, so OEMs - with the same efficiency - can adopt smaller engines). Kohler provides two DPF versions: the first reaches a maximum maintenance interval every 10,000 hours, while the second one is more compact on the market and ensures a maintenance interval of 6 thousand hours. The after-treatment system can be integrated directly into the engine but can also be provided separately, thanks to the axial and radial 360 ° rotation of the sleeves, which guarantees the highest level of adaptability to each application. For operations that require simple and compact solutions, the KDI version without Charge Air Cooling (CAC) offers OEMs a competitive solution characterized by reduced overall dimensions with the same torque and power.