Comer Industries, advanced solutions for components

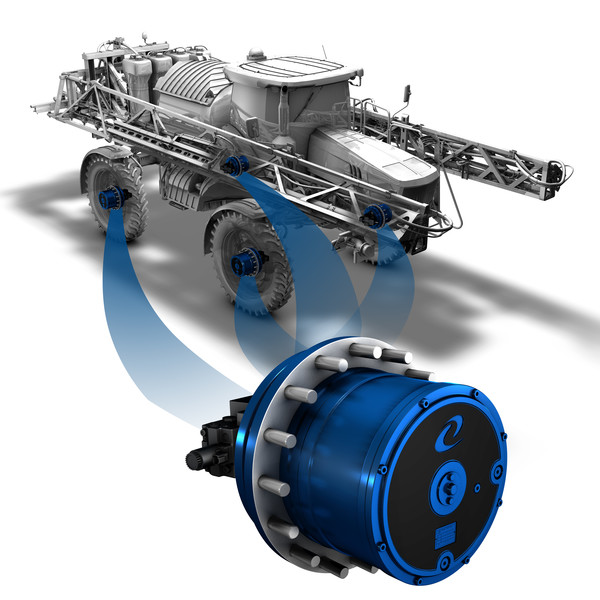

As per tradition, the Comer Industries from Emilia presented the most innovative solutions for the component industry at Agritechncia. Below are the main innovations launched in Hanover. Transmissions for self-propelled misters. With their two-stage gearboxes, a maximum output torque of 18,000 Nm to 48,000 Nm, and tapered roller bearings with high load capacity, the design of this series of drive wheels is particularly suitable for misters up to 20 tonnes. Comer Industries planetary gearboxes are equipped with negative parking brakes with hydraulic control. On request, there is the option of dynamic brake integrated with oil bath discs, operating as a device for both parking and emergency. On this product line, one can choose from a wide range of ratios, from 15 to 50, for greater flexibility in selecting the size of hydraulic motors, ensuring the most suitable solution for the end user’s needs. Transmission Pump Drive. This is a solution designed by Comer Industries specifically for sugar cane harvesting machines. The gearbox, the heart of the technology by the Emilian company, provides movement to the pumps through the internal combustion engine. Its main function is to manage not only the transmission, but also all the devices used for harvesting. The oil circulation inside the transmission was refined using a dedicated software and was tested at the Mechatronics Research Centre of Comer Industries, to guarantee optimal operating temperatures and high performance.

Engine Drive transmission. This technology, on the other hand, was designed for combine harvesters. The gearbox is managed directly by the engine and transmits power to the main functions of the machine: head, rotors, pumps to drive the machine, and auxiliary connections.

By using two completely independent hydraulic clutches, it is possible to control the operation of the head and the rotors, used respectively in the harvesting and threshing of the product.

The aluminium alloy design reduces the overall weight of the combine harvester, while the particular design of the entire kinematic chain improves performance and extends the gearbox’s life cycle. The transmission can work with power peaks up to 550 horsepower.