The versatility of the new rotary harrow for BCS

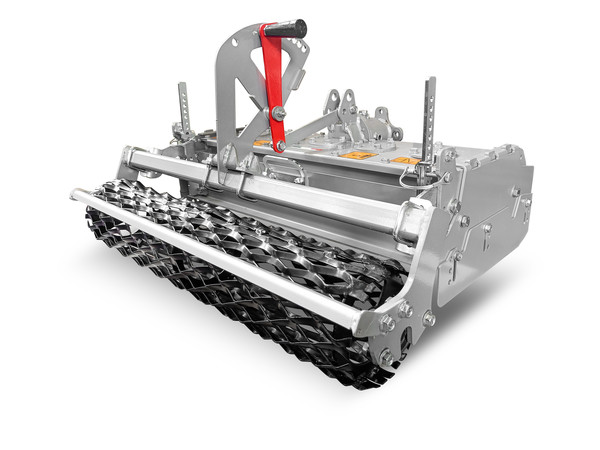

BCS is expanding its range of equipment by adding to its portfolio a new rotary harrow specifically designed for two-wheel tractors and intended for seedbed preparation, combining soil cultivation and leveling in a single operation. The harrow features five counter-rotating rotors, each fitted with a pair of blades that rotate on a vertical axis, unlike a rotary tiller, where the blades rotate on a horizontal axis. The rotating blades break up larger soil clods, creating a uniform seedbed suitable for seed germination and root development. One of the machine’s key strengths is the rear mesh roller. Made of steel and wider than the harrow’s working width, it serves a dual function: it allows adjustment of the blade working depth and completes the cultivation process by leveling the soil and further improving the seedbed. By setting the roller in the transport position, the two-wheel tractor can move to and from the field without removing the implement. An anti-clogging scraper blade also helps keep the roller free from stones or soil buildup. The new implement is therefore used for soil refinement after plowing, seedbed preparation, incorporation of crop residues or fertilizers into the soil, and surface leveling. BCS also sees it as a valuable support for horticultural operations, which require precise soil refinement, as well as for green area maintenance aimed at creating new lawns or working in particularly confined spaces. Added to this is its role in the mechanical control of weeds in organic farming. A look at the technical details: the BCS rotary harrow weighs 78 kg, has an overall width of 850 mm, a working width of 750 mm, and a working depth of approximately 120 mm. The company from Abbiategrasso (Milan) indicates a minimum power requirement under standard conditions of 6.3 kW, just over 8.5 Hp.