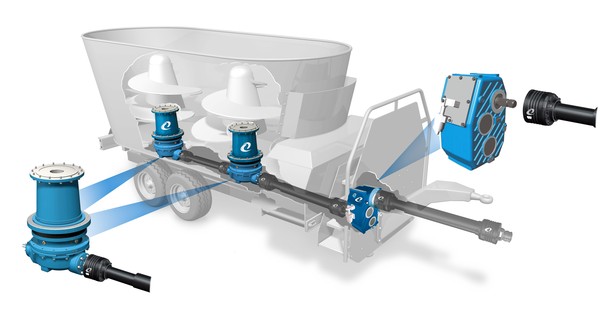

Comer Industries, innovative solutions for mixers

Among the many new products launched by Comer Industries at Agritechnica, particular attention should go to the component solutions for towed mixers. Some items that stand out in this range are the A-613 parallel axes group, the PGA-4203 VM epicyclic reduction gear for actuating augers, and the PGA-2100 VM compact epicyclic reduction gear. The A-613 gearbox, equipped with an electric actuator and featuring the readiness for integration with the ISOBUS protocol, is characterized by low noise and high transmission efficiency, made possible by the use of helical gears. Also of note, the highlights of this component include the internal preload mechanism (eases gear shifting) and the readiness for the pump attachment. The A-613 group is suitable for trailers with two and three augers, with capacities starting at 30 m³. It is available with different speed ratios (1:1/1.8:1 - 1:1/1.5:1 – 1:1/1.3:1 - 1.8:1/2.7:1) with a power rating of 180 hp at 540 rpm. The A-613 transmission, as explained in a technical note from the manufacturer, is part of the Mix@tractor project developed by IDEAgri, the network of Reggio Emilia companies (of which Comer Industries is a part) that produce ISOBUS integrated systems. Thanks to the electrical device for gear changes and the implementation of an ISOBUS sensor for the measurement of torque, the IDEAgri solution allows to read and monitor power absorption, and automatically manage the change phases based on the mixing progress. Moving on to the range of epicyclic gearboxes made by Comer Industries, the PGA-2102 VM model is a compact, high-performance device, combining load capacity and torque transmission (continuous torque: 2,100 daNm, maximum torque: 4,700 daNm) with higher reliability and better resistance to overloads. Meanwhile, the new PGA-4203 VM imposes itself as the largest reduction gear available on the market for this type of application, and has been custom designed for single-auger machines with maximum capacity of 26 m3. The solution has great resistance to heavy loads (max torque 14,200 daNm, input speed 1,000 rpm) and ensures a long life for all the components.