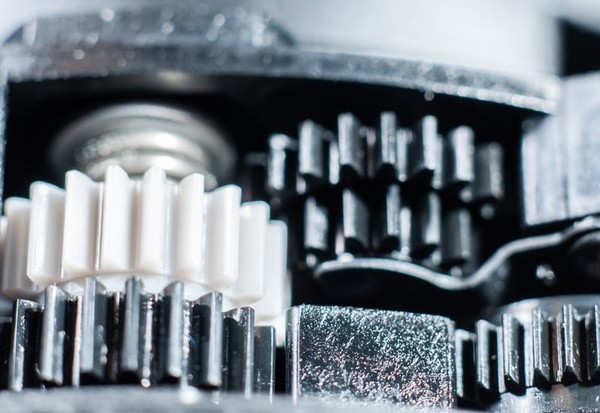

Mecaplast, new polymers for "metal replacement"

Mecaplast of Ghiardo di Bibbiano (Reggio Emilia) can boast over forty years of specialisation in the plastic injection moulding sector. The experience gained since 1976, the in-depth knowledge of polymers and the technologically advanced production plants allow the company to offer a wide range of construction solutions, with high levels of customisation based on the specific needs of each sector. From design to the creation of prototypes, from the choice of the most suitable materials to the construction of the mould, up to accessory and finishing processes, the Emilia-based manufacturer is able to provide a 360° service. Among Mecaplast's areas of specialisation, one of the most important is metal replacement; a field in which the company has established itself thanks to constant updates on new materials, design skills and technological innovation in mould construction and injection moulding. The latest generation of technical polymers have a high level of mechanical and thermal resistance - explains the Emilia-based manufacturer in a technical note - and this characteristic makes it possible to replace components made of metal or other materials. This is a very advantageous solution, since - continues the Mecaplast note - in addition to increasing productivity with obvious economic benefits, it reduces the weight of the product. This means that components made with this type of polymer are less subject to friction forces, dynamic stresses and energy consumption, but also to noise, creep, moisture absorption and deformation, while also increasing their resistance to corrosion and chemical agents. The use of technopolymers also makes it possible to create parts with complex geometries and customised colours. For the Reggio Emilia-based manufacturer, one of the most successful examples of the application of polymers is the creation of the Greenlifetire wheels for seeders, which are strong, light and 100% recyclable. Greenlifetire is not the only solution proposed by Mecaplast for the primary sector, as the company from Ghiardo di Bibbiano also produces other components for transplanters and seeders using polymers instead of steel or aluminium. In the field of hydraulics, then, the manufacturer has developed components capable of working in an oil bath and at temperatures of over 220°. Technopolymers - concludes the manufacturer - are very versatile materials that offer a wide range of technical solutions applicable in many sectors.