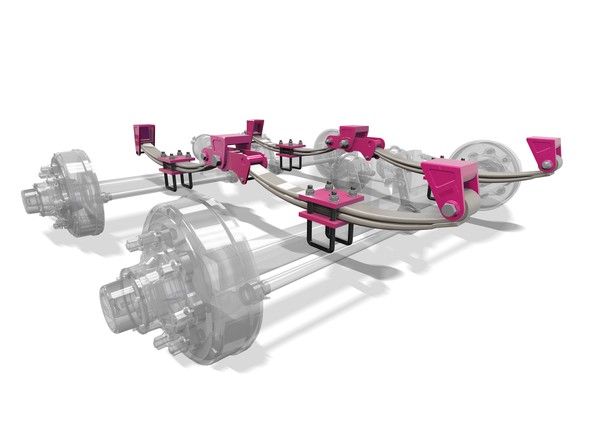

KA, the zero-maintenance suspension

The KA mechanical suspensions have been developed by the Lombardy-based company ADR (based in Uboldo, in the province of Varese) with the aim of offering a line of components for intensive use, characterised at the same time by top-level performance and marked resistance to mechanical stress. A range of components that, as the manufacturer itself points out in a technical note, has also been designed to significantly reduce, if not completely eliminate, machine downtime due to maintenance. For each of these needs, Adr has identified and adopted a tailor-made technology.

Routine maintenance work has been eliminated through the introduction of elastic bushings on the kingpins that do not require periodic greasing.

On the other hand, the weight has been reduced thanks to the use of leaf springs with a parabolic profile, which not only make the machine particularly light but also optimise its stability on the most difficult and rugged terrain.

These strength characteristics are accentuated by the axle anchoring system and the suspension construction technology. The KA models have a cast steel structure, designed to adapt to the most demanding stresses. The small operating deformations - reads the catalogue of the Lombardy company - ensure the stable behaviour by the machine in any condition of use, even the most severe, while the absence of welds eliminates the presence of possible breaking points. Finally, the castings make it possible to use geometries that guarantee a further considerable reduction in weight.

KA mechanical suspensions have load capacities of between 4 and 16 tonnes.